In order to provide the operating speed of the bearing at work, under normal circumstances, grease or lubricating oil is used to lubricate the bearing. How do we seal the lubricant when we perform grease lubrication? According to the use of different types of bearings, the bearing grease sealing method will be different. According to the understanding of bearing maintenance knowledge, Eric Bearing Limited will focus on the analysis of the FAG bearing grease sealing method.

1. Precautions for sealing FAG bearing grease:

Different sealing methods of grease may cause unstable temperature rise during initial running-in operation, abnormal temperature rise, long initial running-in time, and even sintering. Therefore, it is necessary to use an appropriate amount of grease and the correct sealing method according to the conditions of use of.

(1) Items to be confirmed before enclosure

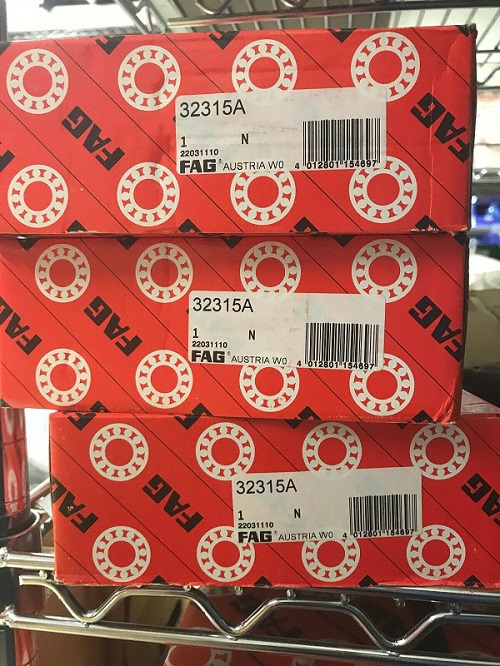

Confirm that there is no residue inside the FAG bearing. It is recommended that the bearings for high-speed spindles should be cleaned, degreased, and then sealed with grease. In other operating conditions, it is also recommended to remove the anti-rust oil adhering to the inside of the bearing. FAG 32315 A bearings online , pls click here :

(2) Enclosure of grease

In order to contain an appropriate amount of grease, it is recommended to use a containment device.

Enclosure, it is best to use a gauge with enclosure reading.

(3) The amount of grease enclosed

Recommended packing quantity for precision bearing standards:

Angular contact ball bearings for high-speed spindles-15% of the inter-volume (-2%~+2%)

Cylindrical roller bearings for high-speed spindles-10% of the inter-volume (-2%~+2%)

Ball bearings for motors-20% to 30% of the space volume.

2. FAG bearing grease sealing method:

(1) Grease sealing method of FAG ball bearings

a. Seal evenly between the steel balls. If the cage is guided by the outer ring to guide the phenol resin cage, it is recommended to apply a thin layer of grease on the guide surface of the cage.

b. Rotate the FAG ball bearing by hand to evenly seal the grease into the raceway surface, the inner diameter of the cage, the steel ball, and the guide surface, so that the grease fills the internal space.

(2) Grease sealing method for cylindrical roller bearings

a. Apply 80% of the enclosed grease evenly on the rolling surface. At this time, it is recommended not to have too much grease on the inner diameter of the cage. The grease inside the cage is difficult to flow during the initial running-in operation stage, which increases the temperature rise and also prolongs the running-in operation time.

b. Apply the grease on the rolling surface of the roller to the end surface of the roller, the cage, the contact part with the roller, and the entrance of the pocket, so that the grease is evenly distributed to the whole FAG bearing.

c. Apply 20% of the enclosed grease evenly and thinly on the raceway surface of the outer ring sleeved in the bearing chamber.

Hot Tags: