FAG bearing parts are short and thin rotating surface bodies. The rotating body determines that the processing machine is relatively single, most of them are lathes and grinding machines; short and thin determine their axial rigidity, axial deformation can be ignored, radial rigidity Poor, special consideration should be given to the tightening method during processing.

Although the structure of rolling bearing parts is simple,but the technical requirements are very high, it has the following processing characteristics:

1.Multi-process processing

FAG bearing parts have high requirements,and there are bound to be many production processes.General bearing production requires 20 to 40 procedures, more than 70 procedures.

2.Precision machining

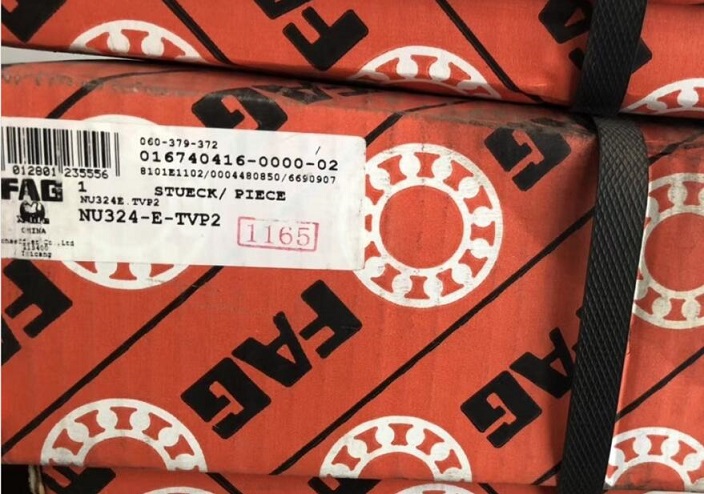

Most of the surfaces of FAG bearing parts have to be ground. The size and geometric accuracy of the grinding are in μM. Especially the precision of the raceway and rolling elements of the ring is higher, and it needs super-finishing or grinding. FAG NU324-E-TVP2 bearings online , pls click here :

3.Molding

The working surfaces of FAG bearing parts are all rotary forming surfaces, which are suitable for processing by forming method. For example, the forging, rolling and turning of the ferrule raceway are processed with forming tools or anti-profile plates.

In addition, the vast majority of bearings are standardized products. The same type of FAG bearings are in great demand. In order to improve productivity, reduce costs, ensure quality and widely use new technologies, improve mechanization and automation, bearing companies generally follow the bearing model The varieties are mass produced, and even special automatic lines or assembly lines can be established for production.

FAG bearing stiffness

The stiffness of FAG bearings refers to the degree of elastic deformation of FAG bearings under load. This deformation is generally small and can be ignored. But in some applications, such as bearings for machine tool spindles or pinion bearings, stiffness is very important.

Cylindrical roller or tapered roller bearings and other roller bearings, because of the linear contact between the rolling elements and the raceway, the rigidity is higher than the point contact ball bearings. Bearing rigidity can be increased by applying preload.

Hot Tags: