Common ways to replace INA bearings

There are two most common ways to replace INA bearings: one is to directly heat INA bearings with acetylene oxygen; the other is to use oil immersion heating for small INA bearings to achieve thermal expansion and expand the inner diameter of INA bearings for assembly. These methods have been widely used in long-term equipment maintenance, basically meeting and solving the problem of INA bearing assembly in equipment maintenance. But these two methods are difficult to determine whether the temperature value of the heated area of the INA bearing is uniform during the heating process. Because the traditional acetylene oxygen heating is a single gas burner, and the heating process is only based on experience, it is difficult to grasp how much the temperature of the heated INA bearing is suitable. If the temperature is too high, the INA bearing will be annealed, reducing the mechanical properties of the INA bearing; if the temperature is too low, the thermal expansion value is not enough, and it is difficult to assemble.

The new method to change the traditional assembly of INA bearing

In the repair of equipment, the repairman sometimes has to heat the INA bearing insufficiently, and the INA bearing cannot be installed in the correct position. Therefore, we propose a new method to change the traditional assembly of INA bearing heating.

1.Use electric heating instead of acetylene oxygen heating

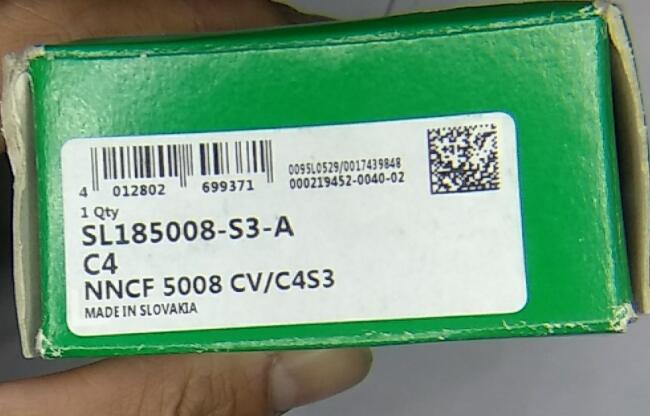

The flat electric furnace is designed as a cylindrical electric furnace, named INA bearing electric heater. According to different INA bearing inner diameter, it can be designed into INA bearing electric heater with different power and specifications (applicable range is INA bearing inner diameter φ300mm / more) . This heating device has the following advantages: uniform and stable heat radiation, no smoke and dust on the surface of the heated INA bearing, clean and clean, easy to measure and control the temperature of the INA bearing. INA SL185008 bearings online , pls click here :

2.Use infrared thermometer to heat

INA bearing surface temperature monitoring. The heating value of INA bearing assembly is generally controlled at 100 ℃ ~ 120 ℃. Within this temperature value, the thermal expansion value of the INA bearing steel is large, which is convenient for the INA bearing assembly. This temperature value will not change the mechanical performance of the INA bearing and has high reliability.

In summary, the INA bearing electric heater is superior to the traditional acetylene oxygen heating, and is an effective method to improve the INA bearing assembly accuracy and working efficiency and reduce labor intensity. 1. A method to improve the accuracy of INA bearings

3.Method of improving accuracy

After the INA bearing is installed in the host, if the radial runout of the main shaft is measured, it can be found that the measured value of each revolution has a certain change; when continuous measurement is performed, it can be found that after a certain number of revolutions, this change will be approximately Repeatedly. The index to measure the degree of this change is the cyclic rotation accuracy. The number of revolutions required for the change to reappear approximately represents the "quasi-period" of the cyclic rotation accuracy. The magnitude of the change in the quasi-period is large, which is the cyclic rotation accuracy.

If the spindle is properly preloaded, the speed will be gradually reduced to close to the mandatory speed to implement the "run-in" effect of the INA bearings, which can improve the cycle rotation accuracy of the spindle.

INA bearing selection summary

The market requirements of various mechanical devices and instruments that use rolling bearings are becoming stricter, and the requirements and performance of bearings are also becoming more diversified. In order to select the most suitable bearing from the numerous structures and sizes, it is necessary to study from various angles.

When selecting an INA bearing, the bearing arrangement, ease of installation, and disassembly as a shafting, the space allowed by the bearing, the size, and the marketability of the bearing are generally considered, which roughly determines the bearing structure. Secondly, while comparing the design life of various machines using bearings and the various endurance limits of the bearings, the bearing dimensions are determined. When choosing an INA bearing, it is often biased to consider only the fatigue life of the bearing, and the grease life, wear, and noise caused by grease aging also need to be fully studied. Furthermore, according to different applications, it is necessary to select the bearings with special requirements for accuracy, clearance, cage structure, grease, etc. However, there is no certain order and rules for selecting INA bearings. The priority should be the conditions, performance, and most related matters that are required for the bearings, which is especially practical.

Influence of external conditions on INA bearings

Vibration can be said to be quite sensitive to damage to INA bearings, and flaking, indentation, rust, cracks, wear, etc. will be reflected in the INA bearing vibration measurement. Therefore, the size of the vibration can be measured by using a special bearing vibration measuring device (frequency analyzer, etc.), and the specific circumstances of the abnormality cannot be inferred by the frequency division. The measured value differs depending on the use condition of the bearing or the installation position of the sensor, etc. Therefore, it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

High temperature is also harmful to the lubricant of INA bearings. Sometimes INA bearing overheating can be attributed to INA bearing lubricant. Long-term continuous rotation of bearings at temperatures exceeding 125 ° C will reduce bearing life. The causes of INA high temperature bearings include: insufficient lubrication or excessive lubrication, lubricants. It contains impurities, excessive load, INA bearing damage ring, insufficient clearance, high friction caused by oil seal and so on.

INA Bearing Assembly Quality Index

The assembly quality index of INA imported bearings, that is, the assembly accuracy requirements are mainly radial clearance and width. There is a certain functional relationship between axial clearance and radial clearance. Therefore, the axial clearance can be indirectly controlled by controlling the radial clearance.

For deep groove ball bearings, cylindrical roller bearings, spherical ball bearings and spherical roller bearings, the radial clearance is mainly controlled.

For thrust ball bearings, thrust roller bearings and tapered roller bearings, the main control height and width.

For angular contact ball bearings, the size of the contact angle is mainly controlled.

The basic requirements for the assembly of INA rolling bearings are: on the premise of guaranteeing the quality index of assembly, the fitting rate is high, and generally it should be more than 95%.

Eric Bearing Limited, Your trustworthy bearing supplier, providing Variety Top Brand Bearings. As a leading bearing distributor in Asia, ERIC BEARING LIMITED has high visibility in our customers, with our products being exported to over 100 countries. We have more than 8 years of export experience that can help you find the ideal purchasing solution. If you are looking for INA bearings or have any questions about bearings, please feel free to contact us.

Hot Tags: