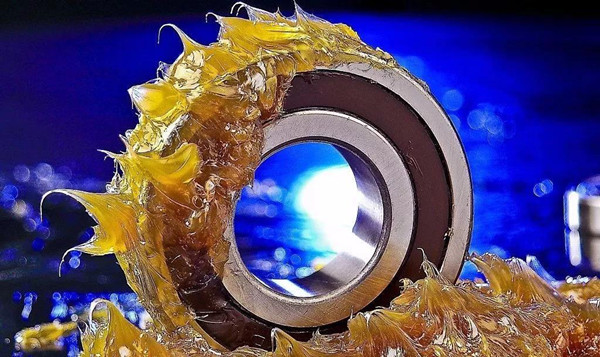

As an indispensable part of modern machinery, the position of bearing is critical, and the maintenance of the regular operation of bearing is almost all the people in the industry must be concerned about. In this case, constant support is bearing lubrication.

Before the inspection of the bearing, the surface of the bearing shall be cleaned first, and then the oil seal of the bearing and its surrounding parts shall be carefully inspected. If there is any bad symptom, it must be replaced. The lousy oil seal will cause damage, and the cloud shape of the bearing will be abnormal, resulting in the shutdown of the equipment.

Pay attention to cover the exposed bearing. Do not expose the bearing to pollutants or moisture when checking the bearing. If the work is interrupted, the machine shall be covered with oil paper plastic sheets or similar materials. If it is possible to clean the bearings without cover without disassembly and inspection, it is necessary to clean them with a brush for coating and oil solvent, and then dry them with a piece of lint-free cloth or with compressed air.

Lubricants are essential. In this regard, not only for a brand of bearings but also covers all kinds of bearings in all brands. However, please note that too much grease should not be applied to Japanese bearings. Also, we should pay attention to changing the lubricant of the bearing. After draining the old oil from the oil-lubricated bearing, if possible, refill with fresh oil and let the machine rotate at low speed for a few minutes. Make the oil collect residual pollutants as much as possible, and then drain the oil. When changing the grease of the bearing lubricated with fat, the arbor remover used shall avoid any part of the bearing contacting with cotton. Because these remaining fibers may wedge between the rolling elements and cause damage, this problem should be paid more attention to in the application of bearings.

Use a small mirror and a probe similar to the one used by dentists to check the bearing's track surface, retainer, and beads. Do not clean the sealed cover or dust-proof bearing, wipe the external surface. Replace the bearing if it is damaged. It is more economical to replace the bearings during the regular maintenance period than the sudden shutdown loss selected due to the damage of the array bearing.

The lubrication and maintenance of bearings are not particularly difficult. Through these three steps, your bearings can be well maintained, to improve the service life of bearings and help the company reduce operating costs. Eric Bearing Co., Ltd. provides not only high-quality customized bearings, such as FAG bearings, SKF bearings, NSK Bearings, NTN bearings, but also offers high-quality services to ensure the quality of products. For example, the company strengthened the quality inspection procedures, established a special quality inspection department, and added equipment such as profile and roughness tester, microhardness tester, bearing service life tester, etc. The price of the product is 30% lower than that of the customer's market. The product is of high quality and low price. Welcome to the order.

Hot Tags: