Ball screw drive systems are used in a large variety of applications where rotational motion needs to be translated into linear motion, with low friction (high mechanical efficiency) and a high degree of preciseness. Typical applications are in aerospace (fly-by-wire), automotive (power steering), precision assembly systems, robots, semiconductor manufacturing (steppers) and machine tools (CNC machines). For high precision (micrometer level) applications where, besides radial loads, also axial forces come into play, special attention to the design of the ball screw drive as well as the ball screw shaft and its bearing support are essential.

JTEKT’s experience in this field

After the integration of Toyoda Machine Works (machine tool manufacturing) and Koyo Seiko (manufacturing of roller bearings) into JTEKT Corporation, in 2006, engineers from both divisions have worked closely together to share their expertise and to optimize the bearings that are required for state-of-the-art machine tools with the high precision that is demanded by the market today. Today , we share KOYO matched bearing structure photo :

The critical role for the ball screw shaft support bearings

While during the development of a new ball screw system typically a lot of attention is paid to the proper design of the ball screw drive (with internal ball recirculating system) and the spindle/ ball screw shaft (precision ground or rolled/cold formed), the importance of the shaft supporting bearings is often underestimated. For applications where ball screw positional accuracy and repeatability is essential (like in machine tools), the shaft bearings must absolutely immobilize the shaft axially when subjected to varying degrees of axial loads from motor power and inertia forces, to avoid backlash.

Single Angular Contact bearings for spindle shaft support

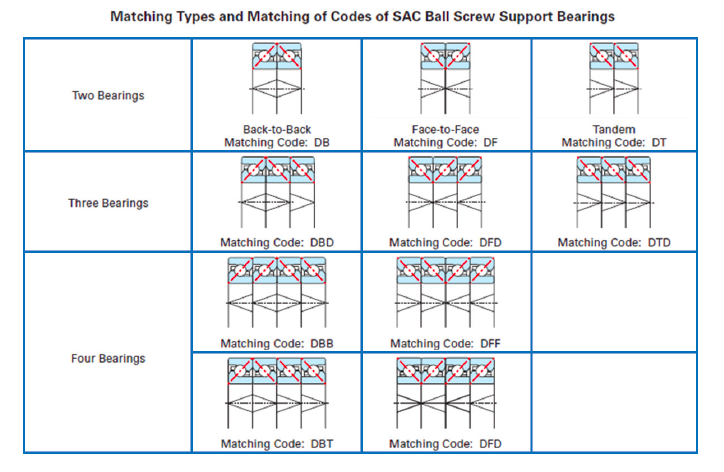

Koyo has developed a dedicated type of SAC bearing with special internal geometry (including a 60° contact angle) that provides maximum running accuracy and the radial/axial load support that is typically required for modern (high speed) machine tool applications, or for applications with similar operational requirements . The SACs can be mounted as a set into a housing or offered as a bearing unit . Different configurations are available to accommodate for the specific application conditions, including two, three or four row matching types and optionally facing in opposite directions to support bi-directional axial loads .

To maintain their inherent accuracy and ensure long life, great care is needed to avoid contamination with dirt and abrasive particles. Precise pre-load setting is imperative to reduce slack (screw shaft axial free play), while optimizing bearing life (cost economy) and minimal internal friction (rotation efficiency – energy consumption). Koyo engineers will advise on the proper configuration, sealing solution and pre-load setting depending on the specific application.

Hot Tags: