What is "quest" called "quest" is the "exploration and pursuit" of high performance and reliability. This is a new trademark on the special high-performance bearing of Nachi industrial machinery. This kind of product condenses the technology accumulated by the company in materials, machining, and lubrication. It can provide users with bearings with high rigidity, strong durability, low noise, excellent environmental protection performance, and world top quality.

Nachi bury company was founded in 1928 and has been committed to the development of machinery technology and machinery manufacturing since its inception. The main factory is located in Fushan, Japan. It has set up permanent representative offices and sales outlets around the world, which can quickly and accurately grasp the market trend and effectively meet customers' wishes.

Nachi products mainly include special steel, cutting tools, bearings, hydraulic devices, robot systems, cutting tools, machine tools, bearings, hydraulic equipment, robots for automatic production, special steel, ultra-precision machinery for IT industry and its environmental policies. Nachi is one of the four famous bearing brands in Japan.

Nachi bearings also have many bearing types, including:

1. Thrust angle contact ball bearing

The contact angle of thrust angular contact ball bearing is generally 60 ° the commonly used thrust angular contact ball bearing is usually a two-way thrust angular contact ball bearing, which is mainly used for the spindle of precision machine tools. It is generally used together with double row cylindrical roller bearings, which can carry the two-way axial load. It has the advantages of high accuracy, excellent rigidity, low-temperature rise, high speed, convenient installation, and removal, etc.

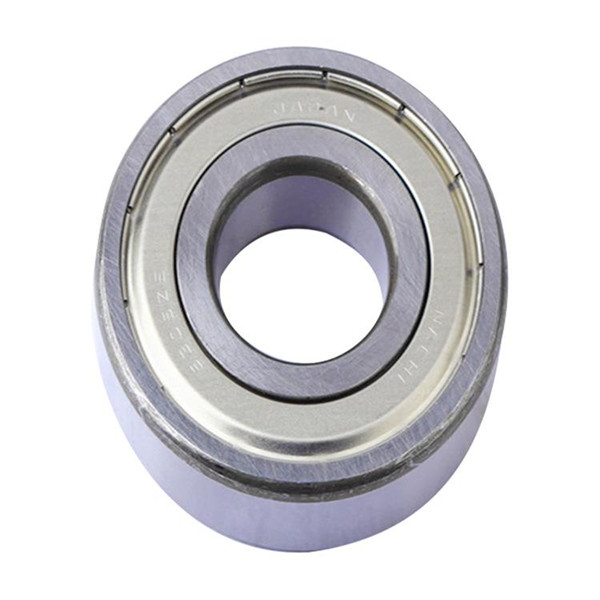

2. Deep groove ball bearing

In structure, each ring of deep groove ball bearing has a continuous groove raceway with a cross-section about one-third of the circumference of the equatorial circle of the ball. Deep groove ball bearing is mainly used to carry the radial load but also can take a specific axial load. When increasing the radial clearance of the bearing, it has the property of angular contact ball bearing and can take the axial load in two directions. Compared with other types of bearings with the same size, this type of bearing has the advantages of small friction coefficient, high limit speed, and high precision, and is the preferred bearing type for users to select. The deep groove ball bearing is a kind of imported bearing with the most massive production batch and the most extensive application range because of its simple structure and convenient use.

3. thrust tapered roller bearing

Because the rolling body of the thrust tapered roller bearing is tapered roller, in structure, the rolling bus and the raceway bus of the washer converge at a certain point on the axis of the bearing so that the rolling surface can form pure rolling. Features: thrust tapered roller bearing can bear unidirectional axial load. The type code of thrust decreased roller bearing is 90000.

4. Double row tapered roller bearing

The double row tapered roller bearing has many structures, most of which are 35000 type. It has a double raceway outer ring and two inner rings. The clearance can be adjusted by changing the thickness of the spacer ring. This kind of bearing can bear both the radial load and the bidirectional axial load and limit the axial displacement of the shaft and the shell within the range of the axial clearance of the bearing. The structural characteristics of tapered roller bearing. The type code of tapered roller bearing is 30000, and the tapered roller bearing is separated bearing. Tapered roller bearings are usually used to bear the combined radial and axial loads, which are mostly radial. Tapered roller bearing can bear axial load in one direction and limit axial displacement of shaft or shell in one direction.

(1) Reduce friction and wear.

The contact parts of the ferrule, the rolling body and the retainer of the bearing prevent metal contact and reduce friction and wear.

(2) Extend fatigue life.

The rolling fatigue life of the bearing is prolonged when the rolling contact surface is well lubricated during rotation. On the contrary, if the viscosity of the oil is low and the thickness of the lubricating oil film is not right, it will be shortened.

(3) Remove friction heat and cold.

Circulating oil feeding method can use oil to discharge the heat generated by friction, or the heat transmitted from the outside, and fresh. Prevent overheating of bearings and aging of lubricating oil.

Hot Tags: