NTN is a world's comprehensive precision machinery manufacturer. It was founded in 1918 in Japan and has 20 wholly-owned production plants, two research institutes, and 48 business offices abroad now. NTN's production, sales, and technology departments strive to unremittingly explore and deepen their professional fields, but also organically integrate. The current chairman is Taixin Suzuki.

NTN standard bearing classification: NTN micro ball imported bearing, NTN deep groove ball imported bearing, NTN centripetal thrust ball imported bearing, NTN self-aligning ball imported bearing, NTN cylindrical roller imported bearing, NTN tapered roller imported bearing, NTN thrust ball bearing, NTN self-aligning roller bearing. Also, the leading products of NTN bearing in Japan include NTN rolling bearing, NTN deep groove ball bearing, NTN high precision bearing, NTN self-aligning bearing, NTN bearing with seat, NTN plane ball bearing, NTN short cylindrical roller bearing, NTN linear guide bearing, NTN ball screw bearing, NTN micro direct guide bearing, NTN cross roller guide bearing, NTN compound rotating bush bearing, NTN shaft Bearing ball slide group, NTN bearing cam-driven bearing.

6203 bearing

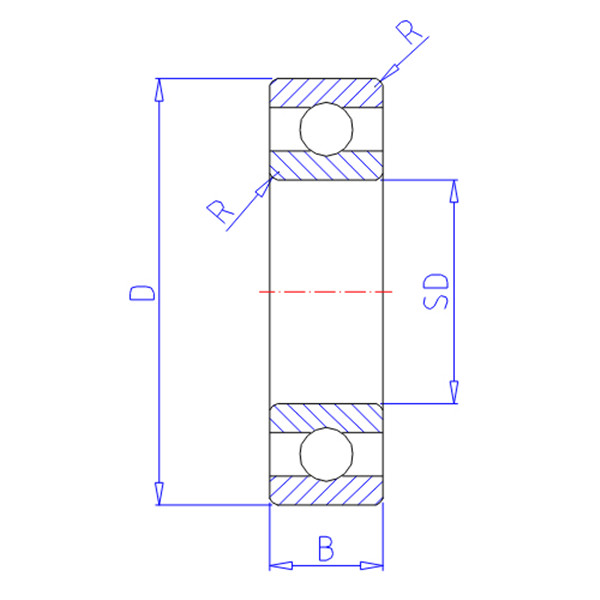

Here, we will focus on a kind of deep groove ball bearing: 6203 bearings. The fundamental introduction of 6203 bearings is as follows: model 6203, inner diameter 17mm, outer diameter 40mm, thickness 12mm, CR9600N, COR4600N, CRF980kgf, CORF465kgf. It is a kind of deep groove ball bearing with a stop groove on the outer ring of the dust cover on both sides. Such products can be divided into Accuracy grades. Generally, if the accuracy is above P5, it is used in machine tools, heavy industrial machinery, and other industries. Its basic structure is shown in the figure below.

Also, people who care about 6203 bearings need to have a precise understanding of 6205 bearings. NTN 6205 bearing is a deep groove ball bearing with an inner diameter of 25mm, the outer diameter of 52mm, and a width of 15mm. Its bearing parameters are dynamic load co14, static load cor7.85, grease lubrication 13000, oil lubrication 15000, and weight (kg) 0.128.

NTN 6205 bearing is the most representative rolling bearing, which is widely used. It is suitable for high-speed and even extremely high-speed operation, and it is very durable without regular maintenance. This kind of bearing has a small friction coefficient, high limit speed, simple structure, low manufacturing cost, and high manufacturing accuracy. It is widely used in precision instruments, quiet noise motors, automobiles, motorcycles, general machinery, and other industries. Mainly bear radial load, but also can take a certain amount of axial load.

This bearing is mainly used in the fields of scraper conveyor, scale conveyor, shaftless screw conveyor, heat resistant scraper conveyor, clinker conveyor, screw conveyor, air cushion belt conveyor, bag cement loader, roller conveyor, etc.

There are many types and models of NTN bearing, limited to the space of this paper, only two of them are introduced here, but the importance of NTN bearing cannot be underestimated. Here is a little knowledge of NTN bearing:

When checking NTN bearings, do not expose them to pollutants or moisture. If the work is interrupted, the machine shall be covered with oil paper plastic sheets or similar materials. To judge whether the removed NTN bearing can be reused, it is necessary to check its dimensional accuracy, rotation accuracy, internal clearance, mating surface, raceway surface, cage, and sealing ring. The inspection results can be judged by those who use inertia bearing or are proficient in bearing.

The criteria of judgment vary according to the mechanical properties and importance, as well as the inspection period, etc. In case of the resulting damage, NTN bearing shall not be reused and must be replaced.

Fracture and defect of bearing parts.

b) Peeling of the rolling surface of the raceway surface.

When the NTN bearing is removed for inspection, first make appearance records by photography and other methods. Also, confirm the amount of residual lubricant and sample the oil before cleaning the bearing.

a. The cleaning of NTN bearing is divided into rough cleaning and excellent cleaning, and a metal grid can be placed at the bottom of the used container.

b. During rough cleaning, use a brush in the oil to remove the grease or adhesive. At this time, if the bearing is rotated in the oil, pay attention to damage to the rolling surface due to foreign matters.

c. During excellent washing, slowly turn the NTN bearing in the oil, and it must be carried out carefully.

Generally, the detergent used is neutral diesel oil or kerosene without water, and a warm alkaline solution is sometimes used as required. No matter what kind of cleaning agent is used, always filter and keep clean. After cleaning, apply antirust oil or grease on NTN bearing immediately.

Hot Tags: