Processing technology of INA bearing parts

INA bearing Company is a subsidiary of Schaeffler Group, Germany INA bearing Company, which was founded in 1946 and headquartered in Nuremberg, Germany. Germany INA bearing company since its establishment has been committed to product innovation, in order to meet the needs of customers and to provide a high-quality guarantee, make it become the world's leading supplier of rolling bearings and automobile manufacturers recognized partner.

1.INA imported bearing steel ball processing

The processing of steel balls for INA bearings is also different depending on the state of the raw materials. The processes before frustration or smooth balls can be divided into the following three types, and the processes before heat treatment can be divided into the following two types. process are: cold punching or wire bar (bar after some cold-needed punch annulus and annealing) -setback cut, coarse, soft grinding or ball of light -heat treatment -hard grinding -grinding -lapping or polishing -Final inspection grouping -rust prevention, packaging -storage.

2.The processing of INA bearing rings

The processing of the inner and outer rings of INA bearings differs according to the raw material or the form of the blank. Among them, the processes before turning can be divided into the following three types. The entire processing process is: bar or tube (some bars) Subject to forging and annealing,normalizing) -Turning -Heat treatment -Grinding -Lapping or polishing -Final inspection of parts -Anti -rust -Storage -(to be matched with the package)

3.The processing of INA bearing cage

Depending on the design structure and raw materials, the processing of INA bearing cages can be divided into the following two categories:

(1)Sheet metal -shearing -punching -stamping forming -shaping and finishing -pickling or shot blasting or stringing -final inspection -rust prevention, packaging -storage (to be matched with the package)

(2) Machining process of solid cage:

The processing of solid cages differs according to the raw materials or the damage of the wool.Among them, before turning, they can be divided into the following four rough types.The entire processing process is: bar, tube, forging, casting -car inner diameter, Outer diameter,end face, chamfering -drilling(or hole drawing,boring) -pickling -final inspection -rust prevention, packaging -warehousing (to be packaged).

4.Machining process of INA bearing roller

The processing of the rollers differs according to the different raw materials.The processes before heat treatment can be divided into the following two types.The entire processing process is: bar turning or wire cold heading, string endless belt and soft grinding -heat treatment -string soft point -coarse grinding outer diameter -coarse grinding end face - final grinding end face -fine grinding outer diameter -final grinding outer diameter -final Inspection group-anti -rust, packaging -storage (to be matched).

Selection requirements for long-life INA bearings

From the perspective of long life, the selection requirements of INA bearings are:

(1)Select the INA bearing model with high load capacity

When selecting INA bearings, the price of INA bearings should be taken into consideration, or INA bearings with higher load capacity but more expensive should be used, or ordinary INA bearings should be used to try to extend their life.

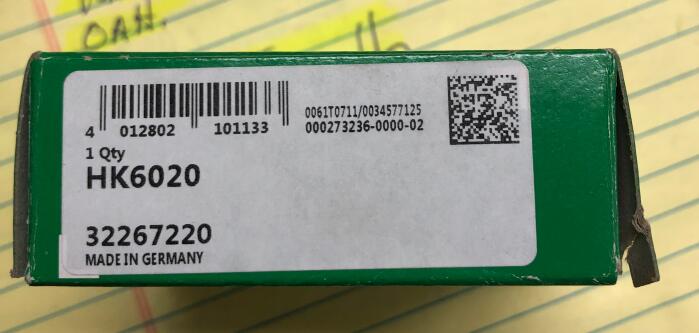

INA bearings with high load capacity are used, such as cylindrical roller INA bearings with convexity, spherical roller INA bearings with symmetrical rollers, reinforced tapered roller INA bearings and ball INA bearings, spherical groove bus corrected balls INA bearings, or replace deep groove (single-row centripetal) ball INA bearings with 70,000CD series INA bearings. These high-load-bearing INA bearings may be higher due to improved stress distribution or due to the larger number of rolling elements Fatigue life. INA HK6020 bearings online, pls click here :

(2)Select the appropriate INA bearing size

To properly select the INA bearing size, the working load, speed and operating temperature of the INA bearing must be accurately calculated or actually checked.

The load has the greatest impact on the life of the INA bearing, so although the load is the most difficult to measure, it must be measured as accurately as possible.When the load measurement is difficult, the actual power consumption of the motor can be measured, and the power loss along the way can be calculated according to the transmission route, until the INA bearing load is calculated that is closer to the actual.The calculated or measured load is too large, and the expected fatigue life of the INA bearing must be reduced by a greater extent, and it must be remedied.If the installation site permits, you can choose an INA bearing with a larger size; if the radial size is limited, you should choose a wider INA bearing in the case of a wider INA bearing; if you can not use a wider INA bearing, you can change Use INA bearings with high load carrying capacity.

(3)Select the appropriate INA bearing material

The choice of INA bearing material must also take into account its price, and when vacuum smelting or electroslag remelting steel has to be used, it must be noted that the lubrication conditions must be perfected to increase the expected fatigue life of the INA bearing.Of course, the cost of selecting INA bearings made of such high-quality steel is much more expensive than the selection of INA bearings with higher load capacity, but for INA bearings that are difficult to access in the machine and difficult to assemble or disassemble, or operating machinery in mines and tunnels For the INA bearings used, it is very difficult to overhaul, and sometimes it must still be considered for use.

How to prevent corrosion of INA bearings

Corrosion, black skin, and pitting, the latter two are defects that are easy to store moisture and dirt, and are most likely to develop into rust.Corrosion is a source of pollution that leads to poor installation, early wear and fatigue. Severe corrosion will make INA bearings scrapped.

The quality of the riveting or welding of the cage, mainly to observe whether the rivet head is misaligned, skewed,slack, lack of meat or "double eyelid", whether the welding position is correct, whether the welding point is too large or too small, whether the welding is not strong or excessive Causes the phenomenon of jamming the rolling body, whether the quality of the pressure slope, edge trimming, caulking and chiseling of certain cages is guaranteed, and whether the rolling bodies can fall out of the cage and can rotate freely. If these points are not satisfactory, the small As a result, the noise and rotation accuracy of the INA bearings are reduced, and the cage may fall apart, causing mechanical failure or accidents.

For the role of relative axial displacement between the fixed shaft and the bearing box, the other side is called the free side, which only bears radial load, and the axial direction can be relatively moved, so as to solve the problem of the shaft due to temperature changes The expansion and contraction problems and the spacing error of installing INA bearings.

For fixed-side INA bearings, you need to select the INA bearings that can use the rolling surface to move in the axial direction (such as cylindrical roller bearings) or move to the assembly surface (such as radial ball INA bearings). On relatively short shafts, when the fixed side is free from the free side, bearings that only move axially in one direction (such as centripetal thrust ball INA bearings) are used.

Install the INA bearing housing on the housing, if there is grease filling hole, it must be aligned with the position.Tighten the INA bearing housing with the tightening bolts coated with anti-loosening glue; tighten the eccentric block tightening bolts, turn the adjustable eccentric block to the angle position before removal and tighten the tightening bolts.After the above assembly is completed, the rotating shaft should have a certain axial series.

The maintenance of bearing disassembly needs to be performed better when it is cleaned. It also records the appearance and confirms the effect of the remaining amount of lubricant. It can be used as a cleaning agent for sampling and inspection. Gasoline and kerosene are generally used. The removed bearing is divided into coarse cleaning and fine cleaning, and placed in the container separately, first put the bottom of the metal mesh pad, so that the INA bearing does not directly contact the dirt of the container.During rough cleaning, if the bearing is rotated with dirt, it will damage the rolling surface of the bearing, so care should be taken.In the coarse cleaning oil, use a brush to remove grease and adhesions. After it is roughly clean, transfer to fine washing.Fine washing is to carefully clean the INA bearings while rotating in the cleaning oil.In addition, the cleaning oil should also be kept clean.

INA bearing cleaning method

There are two methods for cleaning INA bearings:

1.Cleaning method

Soak the INA bearing in kerosene for 5-10 minutes, pinch the inner ring with one hand, and turn the outer ring with the other hand, the dry oil or anti-rust paste on the bearing will fall off.Then put the bearing in cleaner kerosene, wash it with a fine brush, wash the oil stains in the balls and gaps, and then wash it in gasoline once, take it out on clean paper.Radial spherical ball bearings and short cylindrical roller bearings should be cleaned by removing the balls, bead holder, inner ring and outer ring.

The cleaning of the INA bearing mounted on the shaft is mainly by the method of spraying oil or spraying with an oil gun. The oil stains that are easily cleaned are first used with kerosene and then gasoline; the oil stains that are difficult to clean are first sprayed with hot engine oil at 100-200 ℃ Wash or spray with an oil gun, and then clean with gasoline.Be careful not to scrape the bearing with sharp tools: hard grease or rust is formed to avoid damaging the smoothness of the bearing rolling elements and groove ring parts. The cleaned bearings are wiped dry with a clean cloth.

2.Hot oil cleaning method

Due to long-term use, bearings that are hardened with soft dry oil or anti-rust paste should be immersed in hot engine oil at 100-200°C, clamp the bearing with pliers, and clean the oil stain on the bearing with a brush.Soft dry oil or anti-rust paste is melted by heating to 100-200℃, and it is easy to wash out from the gap of the bearing.Sometimes as long as the bearing is shaken in the oil multiple times.Grease will also flow away from the gap.

When cleaning the radial spherical bearings of old motors or imported motors, the balls, bead holders and inner rings should be laterally turned out of the outer rings and then immersed in hot oil. The rollers should also be used when cleaning short cylindrical roller bearings , Bead stand, inner ring and outer ring are disengaged.

When cleaning with hot oil, the temperature of the oil should not exceed 20°C.If using an open flame for direct heating, care should be taken to prevent the oil from burning, the bearing should be hung in the oil pan, and the bottom will cause overheating and reduce the hardness.

The motor should be cleaned and refueled after 2000 hours of use.

Eric Bearing Limited, Your trustworthy bearing supplier, providing Variety Top Brand Bearings. As a leading bearing distributor in Asia, ERIC BEARING LIMITED has high visibility in our customers, with our products being exported to over 100 countries. We have more than 8 years of export experience that can help you find the ideal purchasing solution. If you are looking for INA bearings or have any questions about bearings, please feel free to contact us.

Hot Tags: