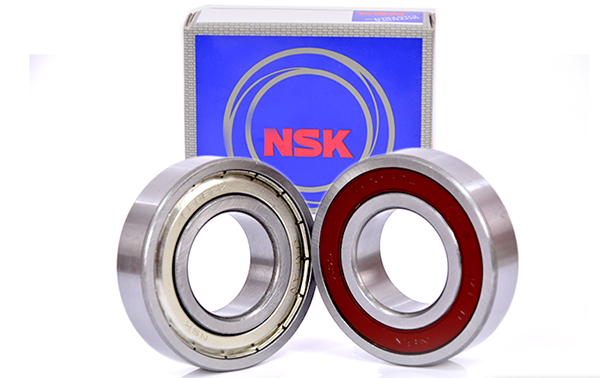

Selection, maintenance and overhaul of NSK bearings

1.Selection of NSK bearings

At present, various mechanical equipment, instruments and other markets have increasingly strict requirements on the performance and quality of NSK bearings, and the working environment of bearings has become more and more diverse. it is necessary to analyze and study from multiple angles. When selecting a bearing, generally consider the ease of installation, arrangement, and disassembly of the bearing as a shafting, the size of the bearing, the allowable space, and the marketability of the bearing, etc., and first determine the bearing structure. Second, determine the size of the bearing to be selected while comparing the mechanical design life of the equipment using the bearing and the durability limit of various NSK bearings. In addition to considering the fatigue life of the bearing, we should also thoroughly consider the grease life, wear, noise and other factors related to the aging of the grease when selecting the bearing. According to the different uses of the bearing, the bearing clearance, accuracy, cage structure, and fat should also be made corresponding requirements, and the bearing can be specially designed when necessary. There is no specific order and rules for selecting bearings, and relevant conditions such as the conditions and performance of the required bearings should be considered according to the actual situation.

2. NSK bearing maintenance

During the use of NSK bearings, to ensure the proper use, performance and life of the bearings, it is necessary to perform necessary maintenance on the bearings to ensure the stability and reliability of NSK bearings, improve work efficiency and reduce work costs. The support of the bearings needs to be performed regularly. The operating status of the bearings is monitored according to the prescribed standards, including the bearing's rotation factor, vibration, temperature, etc., and the lubricants are regularly replenished or replaced, and systematically disassembled and inspected.

3. Maintenance of NSK bearings

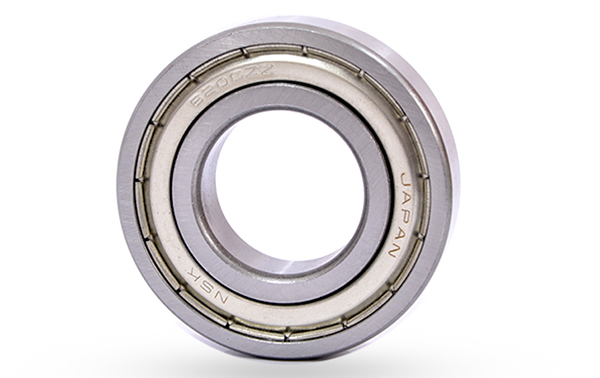

After removing the bearing, the first record the appearance of the bearing to be inspected, confirm the remaining amount of lubricant and sample the oil for inspection, and clean the bearing. Bearing cleaning is divided into coarse cleaning and excellent cleaning. Put the bottom of the metal mesh in the container first to avoid the bearings directly contacting the dirt in the box. To prevent damage to the rolling surface of the bearing during rough cleaning, be careful not to rotate the bearing with soil. Use a brush to remove the grease and stickies from the bearings in the coarse cleaning oil, and then clean them carefully. Let the bearings be cleaned while rotating in clean, clear oil.

After the bearing is cleaned, check the state of the raceway surface, rolling surface, mating surface of the NSK bearing, the increase of bearing clearance, the wear of the cage, and any damage that affects the reduction of dimensional accuracy to determine whether the bearing is working correctly. Non-separable NSK bearings can first keep the inner ring of the bearing horizontal, and rotate the outer ring to see if the bearing runs smoothly. For separate bearings such as tapered roller bearings, the rolling elements and the raceway surface of the outer ring can be inspected separately.

Examples of bearing damage, such as seizing of spherical roller taking rings, have various reasons: for example, insufficient lubricant, improper, imperfect oil supply and drainage structure, foreign matter mixed in, incorrect bearing installation, and large shaft deflection and many more. Therefore, it is sometimes difficult to find out the cause by merely investigating bearing damage. However, as long as you understand the main engine using the bearing, the user requirements, the bearing peripheral structure, and the situation before and after the accident, you can comprehensively analyze the bearing damage and many reasons to prevent similar accidents from happening again.

Hot Tags: