The type of machinery is different, the service conditions of the bearings will be different, and the performance requirements are also different. Generally speaking, there are no less than two bearings used on a shaft.Moreover, in order to facilitate the axial positioning, most of the bearings are used as fixed-end bearings, and the rest are used as free-end bearings. The following table lists the choice of fixed end and free end bearing structure.

Content Applicable Bearing Type

Fixed-end bearing: used to locate and fix the bearing axially. Select bearings that can bear radial and axial loads at the same time. In order to withstand the bidirectional axial load, it is necessary to consider the corresponding strength according to the size of the axial load during installation. Deep groove ball bearing combined angular contact ball bearing, double row angular contact ball bearing, self-aligning ball bearing, cylindrical with rib, roller bearing (NUP type, NH type) .

Spherical roller bearings

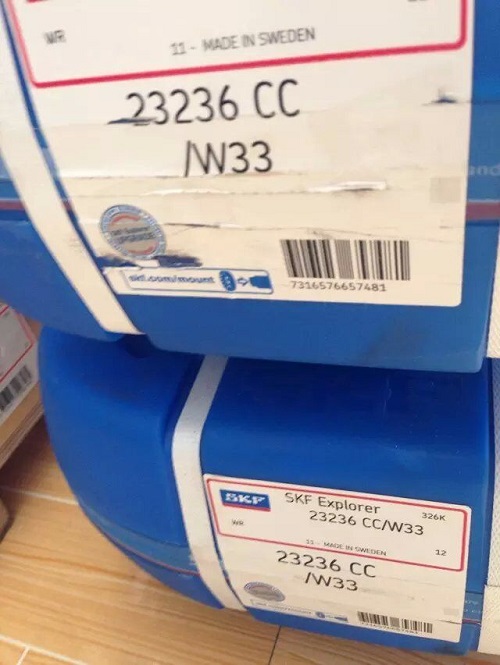

Free end bearing: used to avoid the expansion and contraction of the shaft caused by temperature changes during operation, and to adjust the axial position of the bearing. It is advisable to choose a bearing that only bears radial load and the inner ring and outer ring can be separated. When using non-separable bearings, a clearance fit is generally adopted between the outer ring and the housing, so that the shaft can be extended and retracted together with the bearing for axial avoidance. Used to avoid the temperature during operation . Large Quantity of SKF 23236 CC/W33 bearings in stock , pls click here :

The expansion and contraction of the shaft caused by the change and the adjustment of the axial position of the bearing. It is advisable to select a bearing that only bears radial load and the inner ring and outer ring can be separated. When using non-separable bearings, a clearance fit is generally adopted between the outer ring and the housing, so that the shaft can be extended and retracted together with the bearing for axial avoidance. When the fixed end and the free end are not distinguished, when the bearing spacing is small and the influence of shaft expansion and contraction is not large, it will be able to two angular contact ball bearings or tapered roller bearings that can bear axial load are configured on the front or back.

Adjust the axial clearance after installation with nuts or washers. Deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, cylindrical roller bearings (NJ type, NF type), tapered roller bearings, spherical roller bearings are used for vertical shafts when the fixed end is selected to bear radial load and Bearings with axial load. When the axial load of the axial load bearing is large, the thrust bearing and the radial bearing are used together. In this way, the free end uses a bearing that can only bear radial load to avoid expansion and contraction of the shaft. Fixed-end combined angular contact ball bearings (back combined) double-row tapered roller bearings (37000 type) thrust bearings and radial bearings are used together.

Install

Bearings are precision mechanical parts, please do not open the package before installation to avoid rust. For grease lubricated bearings and oil seals or dust caps on both sides, the sealed ring bearings can be installed directly without cleaning.

Method

In the process of bearing installation, a principle must be mastered, that is, the installation force or moment can only be transmitted through the corresponding ring.

Press fit

When the inner ring of the bearing is tightly fitted with the shaft, and the outer ring is loosely fitted with the bearing seat hole, the bearing can be press-fitted on the shaft with a press, and then the shaft and the bearing are installed in the bearing seat hole. On the end face of the inner ring of the bearing, an assembly sleeve made of soft metal material (copper or mild steel) is cushioned.

The outer ring of the bearing is tightly fitted with the housing hole. When the inner ring and the shaft are loosely fitted, the bearing can be pressed into the housing hole first. At this time, the outer diameter of the assembly sleeve should be slightly smaller than the diameter of the housing hole.

If the bearing ring is tightly fitted with the shaft and the seat hole, the inner ring and outer ring must be installed into the shaft and the seat hole at the same time. The structure of the assembly sleeve should be able to tighten the end faces of the inner ring and the outer ring at the same time.

Heating coordination

By heating the bearing or the bearing seat, thermal expansion is used to transform the tight fit into a loose fit installation method. It is a common and labor-saving installation method. This method is suitable for the installation of bearings with large interference. Before hot assembling, put the bearing or separable bearing ring into the oil tank and heat it evenly at 80-100℃, then take it out of the oil and install it on the shaft as soon as possible. Prevent the inner ring end face and shaft after cooling .

Should not fit tightly, the bearing can be tightened axially after cooling. When the outer ring of the bearing is tightly fitted with the light metal bearing seat, the hot-fitting method of heating the bearing seat is adopted to avoid scratches on the mating surface.

When heating the bearing with an oil tank, there should be a grid at a certain distance from the bottom of the box. The bearing should be hung with a hook. The bearing cannot be placed on the bottom of the box to prevent sinking impurities from entering the bearing or uneven heating. There must be a thermometer in the oil tank. Control the oil temperature not to exceed 100°C to prevent the occurrence of tempering effects and reduce the hardness of the ferrule.

Hot Tags: