NTN company is one of the world's comprehensive precision machinery manufacturers. The company was founded in Japan in 1918 and is headquartered in Nishi-ku, Osaka. There are 11 manufacturing plants, 25 sales offices, and 3 research institutes in Japan. 20 wholly-owned production plants, 2 research institutes, and 48 business offices. NTN's production, sales, and technology departments work tirelessly to explore and deepen their professional fields, while at the same time organically combining each other.

NTN bearings are a type of famous bearing brand. The technology of NTN company has reached the world's only nanometer unit size-nanometer level precision, and this precision has been used in orbiting satellites, aviation, railways and automobiles, papermaking equipment, Various sectors of industrial sectors such as office equipment and food machinery.

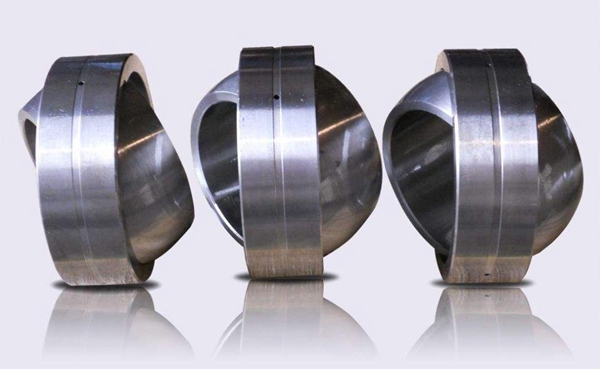

The spherical plain bearing is a spherical plain bearing. Its sliding contact surface is an inner spherical surface and an outer spherical surface. It can rotate and swing at any angle during movement. It adopts a variety of special processes such as surface phosphating, frying, inlaying, and spraying methods. Spherical bearings have the characteristics of large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning, and good lubrication.

The structure of a spherical plain bearing is simpler than that of a rolling bearing. It is mainly composed of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. Spherical bearings are generally used for low-speed oscillating motion (that is, angular motion). Because the sliding surface is spherical, it can also perform tilting motion (that is, self-aligning motion) within a certain angle range. When the degree is large, it can still work normally.

Spherical plain bearings is widely used in engineering hydraulic cylinders, forging machine tools, construction machinery, automation equipment, automobile shock absorbers, hydraulic machinery, and other industries. The basic type of spherical plain bearings consist of inner and outer rings with a spherical sliding contact surface. Depending on the structure and type, it can bear radial load, axial load, or combined load acting simultaneously in radial and axial directions.

Because of the large spherical sliding contact area of the spherical plain bearing and the large inclination angle, at the same time, most spherical plain bearings adopt special processing methods, such as surface phosphating, galvanizing, chrome plating or outer sliding surface lining, inserts, spray coating, etc. Therefore, it has a large load capacity and impact resistance and has the characteristics of corrosion resistance, wear resistance, self-alignment, good lubrication, or self-lubrication without lubrication pollution. It can work normally even if the installation is misplaced. Therefore, spherical plain bearings are widely used in low-speed swing motions, tilt motions, and rotary motions.

The allowable operating temperature of a spherical plain bearing is mainly determined by the paired materials between the bearing sliding surfaces, especially the plastic material sliding surface of the self-lubricating spherical plain bearing, and its bearing capacity will decrease at high temperature. For example, when the sliding surface material of the lubricated spherical plain bearing is steel, its allowable operating temperature depends on the operating temperature of the lubricant. However, for all lubricated and self-lubricating spherical plain bearings, they can be used in the temperature range of -30 °C to + 80 °C and maintain the correct bearing capacity.

Hot Tags: